Advanced Integration with X-Ray Spectrometers

Instant Composition Intelligence. Uncompromised Alloy and Purity Control.

In metallurgy, mining, aerospace, and precision manufacturing, verifying material composition is not a checkpoint, it is mission-critical. The DaVinci Quality Management module integrates directly with leading X-ray Spectrometry systems, enabling real-time chemical analysis, automated validation, and full traceability without manual effort. From handheld XRF devices to automated spectrometers, DaVinci ensures every reading is accurate, every record secure, and every decision driven by live, lab-grade data.

What the Integration Enables

Automated Material Verification

Spectrometer readings are automatically captured during goods inspection, melt verification, or process sampling. Results are compared against defined grade libraries and tolerance benchmarks in real time. Any failed match instantly generates alerts, CAPA workflows, or process holds without operator intervention. This ensures quality deviations are corrected immediately, reducing risks, eliminating manual error, and building complete trust in material integrity across every stage of manufacturing, from receipt through production

Certified Analysis Reports

Composition certificates are automatically generated and attached to shipping records, inventory, or customer documentation. Formats can be customized for ISO, ASTM, or customer-defined requirements, ensuring compliance across global supply chains. Reports remain securely stored and traceable, instantly accessible when required for audits or deliveries. This automation eliminates paperwork, reduces administrative overhead, and ensures buyers receive verified composition data upfront building trust, improving efficiency, and streamlining operations across every quality checkpoint seamlessly.

Real-Time Composition Data in MES

Elemental composition profiles such as Fe, Al, Mg, Zn, and Cu are streamed directly into DaVinci’s MES, appearing in Quality Dashboards and Batch Logs in real time. Each entry automatically links to heat numbers, lot identifiers, and work orders creating complete traceability. By integrating inspection with MES, compliance becomes effortless, reporting remains transparent, and manufacturers gain a unified data source that accelerates decision-making while ensuring accuracy across regulatory and operational requirements.

Closed-Loop Feedback to Production

Detected variations in alloy purity, chemical balance, or elemental deviations automatically adjust connected parameters in furnaces or CNC machines. This closed-loop control ensures defects are prevented at the source, avoiding costly rework or wasted production. By resolving issues upstream, quality consistency improves while efficiency and yield remain optimized. The system delivers predictive, proactive manufacturing bridging inspection with process control seamlessly to maintain stable, reliable production without unnecessary manual intervention or delay.

Key Technical Benefits

Advanced capabilities designed for modern manufacturing environments

No Manual Data Entry

Eliminate human error and reduce labor costs with automated data capture.

Configurable Thresholds

Set custom tolerance limits for every parameter to ensure precision.

Digital Signatures & Audit Trails

Ensure traceability with secure digital approvals and logs.

Cloud or Edge-Enabled

Deploy seamlessly in your environment whether centralized or decentralized.

Multi-Device Support

Access insights and controls from desktop, tablet, or mobile devices.

Supported Integrations

Easily expandable via APIs or integration tools.

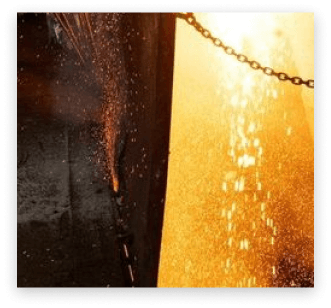

Real-Time Traceability from Ladle to Pour

Ladle Prepped

Molten aluminium prepared instantly for safe pouring.

Composition Scanned

XRF analyzer verifies melt composition in real time.

Deviation Detected

Out-of-spec readings trigger automatic hold instantly.

.png&w=3840&q=75&dpl=dpl_5YPNS4Y7tTVw4LaNQmeBzB7xne7k)

Outcomes & Value

Make every process faster and more reliable.

DaVinci makes material science operational.

Spectrometer insights are no longer locked in silos they’re embedded directly into your digital factory.