DaVinci fuses Artificial Intelligence and the Internet of Things to create an intelligent, self-correcting factory floor. Every sensor, system, and machine becomes part of a unified intelligence delivering real-time insights, predictive control, and measurable efficiency gains.

AI predicts failures early, reducing downtime and extending equipment lifespan.

IoT streams adjust parameters continuously, improving yield, efficiency, quality.

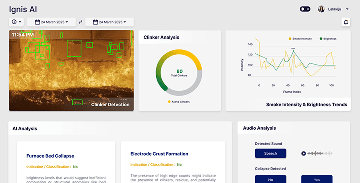

Dashboards deliver instant intelligence, guiding operators, managers, executives effectively.

MES, ERP, PLCs, IoT converge seamlessly into a unified platform.

Systems self-correct automatically, ensuring quality, reducing rework, and minimizing scrap.

AI predicts failures early, reducing downtime and extending equipment lifespan.

IoT streams adjust parameters continuously, improving yield, efficiency, quality.

Dashboards deliver instant intelligence, guiding operators, managers, executives effectively.

MES, ERP, PLCs, IoT converge seamlessly into a unified platform.

Systems self-correct automatically, ensuring quality, reducing rework, and minimizing scrap.

Break Down Silos

Unify machines, processes, and enterprise data into one intelligence fabric, eliminating fragmentation and enabling true end-to-end visibility.

Boost Sustainability

Automated energy tracking, carbon monitoring, and ESG reporting — aligned with ISO, CSRD, and GHG standards for effortless compliance.

Enhance Safety & Reliability

Detect stress, slag, and combustion anomalies before they escalate, preventing accidents, protecting assets, and saving costs.

Scale Without Limits

Deploy seamlessly across plants, lines, or global networks. DaVinci adapts to complexity without compromising consistency or performance.

IoT devices capture live data from machines and sensors.

AI detects inefficiencies, risks, and opportunities instantly.

Automated corrections fine-tune processes in real time.

Dashboards update continuously with ESG, cost, and quality metrics.

15–20%

Improvement in throughput and yield

20–30%

Less unplanned downtime

10–15%

Lower energy and emissions footprint

Instant

Decision-making across operations and leadership

Computer vision + IoT sensors detect clinkers, optimize melt quality, and extend furnace life.

AI tracks energy in real time, reducing waste and ensuring ESG compliance reporting.

Operators receive live, rule-based instructions reducing errors and enhancing consistency.

Other systems provide raw data. DaVinci delivers actionable intelligence